Mining never flows clean. Iron ore slurry, copper concentrate, gold tailings, and coal fines are dense, abrasive, and corrosive. Valves in this environment need to do more than just open and close — they need to survive. At Phoenix ValSteer, we manufacture knife gate valves, check valves, and isolation valves designed for high-solid, high-wear flow.

From iron mines in Brazil to gold operations in South Africa, our valves perform reliably where others wear out fast.

Why Flow Control Matters in Mining

Mining operations depend on high-performance valves to isolate, direct, and regulate material-heavy flow. Whether you’re handling tailings, dewatering lines, or chemical processing systems, each valve must resist erosion, scaling, and corrosion — without constant maintenance or failure.

Phoenix ValSteer delivers valves made specifically for this harsh duty.

Common Challenges in Mining Applications

- Abrasive solids in ore slurries and mineral concentrate lines

- Scaling and clogging from suspended particles and fines

- Corrosive chemicals in leaching and reagent systems

- High-cycle operations in dewatering and backfill systems

- Remote locations where downtime is costly

- Temperature and pressure fluctuations in multiple stages of processing

Where Our Valves Are Used

- Iron ore operations in Australia and India : Knife gate valves in pellet and beneficiation plants

- Copper mines in Chile and Peru : Gate and check valves for tailings and concentrate transfer

- Gold and platinum mines in South Africa : Class 600 globe and ball valves for isolation and throttling

- Nickel and bauxite mines in Indonesia and Brazil : Lined and stainless valves in chemical processing systems

- Coal wash plants in the U.S. and Asia : Knife gate valves for fines and slurry isolation

Recommended Valve Types and Pressure Classes

Valve Type | Pressure Class | Common Materials | Typical Applications |

Knife Gate Valve | 150 | Duplex, SS316, Hard-Faced | Isolation in slurry pipelines, tailings lines, underflow systems |

Gate Valve | 150–600 | WCB, SS316 | Dewatering lines, pump isolation, utility services |

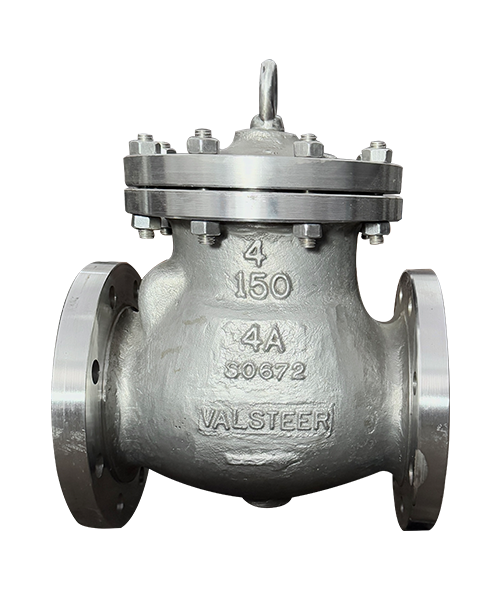

Check Valve | 150–600 | CF8M, Duplex | Backflow prevention in thickener overflow and water circuits |

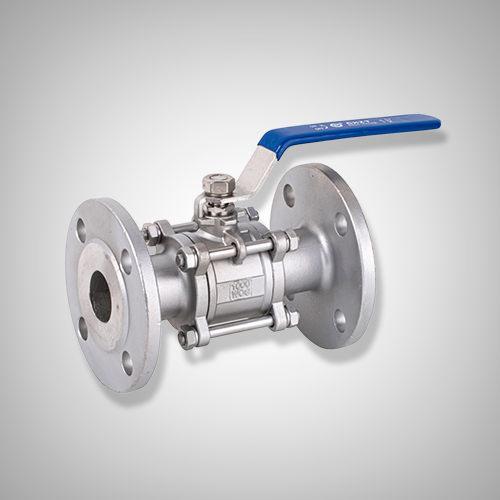

Ball Valve | 150–600 | CF8M, PTFE-Lined | On/off service in reagent, acid dosing, and leach circuits |

Materials for Abrasive and Corrosive Flows

We offer materials that extend valve life in aggressive mining conditions:

- Duplex Stainless Steel : For superior erosion and chloride resistance

- SS316 / CF8M : For corrosion-prone chemical and wash systems

- WCB / Carbon Steel : Ideal for general non-corrosive applications

- PTFE-Lined Valves : For aggressive reagent and leaching fluid service

- Hard-Faced Seats and Discs : For longer life in abrasive and high-cycle flows

All valves can be supplied with test certificates, MTCs, and third-party inspection support.

Why Choose Phoenix ValSteer?

- Performance Proven Globally : Our valves are trusted in mines across South America, Africa, Asia, and Australia

- Engineered for Abrasive Flow : Oversized ports, solid gate design, and replaceable seats

- Custom-Fit Solutions : Responsive to EPC contractors and end users for RFQs, drawings, and replacements

- Built to Minimize Downtime : Maintenance-friendly designs with fewer failures and faster changeouts

Ready to Handle What Your Mine Sends Through the Line?

When solids are flowing, scaling is building, and downtime is not an option — we’re ready. Phoenix ValSteer valves are made for exactly these conditions.