VALSTEER Dual Plate Check Valves : Engineered for Efficiency and Reliability

Phoenix ValSteer is a leading manufacturer of Dual Disc / Dual Plate Check Valves, designed to meet the stringent requirements of diverse industries including Oil & Gas, Petrochemical & Refinery, Fertilizer Plants, Food & Dairy, Drug & Pharmaceuticals, Mining, Steel, Cement, Power, Sugar, Pulp & Paper, and Chemical processing. Our valves are engineered to provide optimal performance with minimal pressure drop, ensuring efficient operation and long service life.

Our VALSTEER Dual Plate Check Valve Ranges

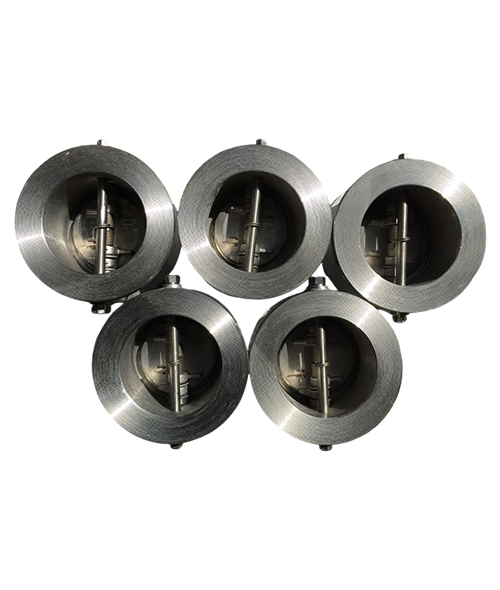

Dual Plate Wafer Check Valve

Dual Plate Lug Check Valve

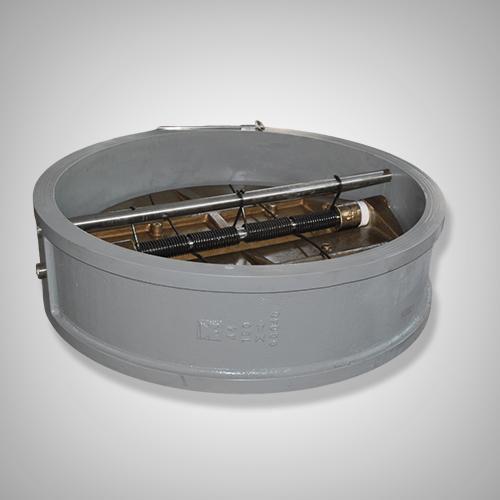

Dual Plate Flanged Check Valve

Size

DN50-DN900

Pressure Rating

150#, 300#, 600#, 900#, 1500#

Design Standard

API 594, API 6D

Seat Type

Metal Seat, Soft Seat (EPDM/Viton/PTFE)

End Connection

Wafer, Lugged, and Flanged – RF/RTJ

MOC

| BODY – BONNET | SEAT/DISC | STEM |

|---|---|---|

| CAST CARBON STEEL ASTM A216 GR.WCB/WCC | 13% Cr. S.S. | A 182 F6 |

| CAST STEEL ASTM A352 GR LCB AND LCC | A351 CF8 | A 182 F304 |

| ALLOY STEEL ASTM A217 GR WC1, WC4, WC5, WC6, WC9, WC11, C5 & C12 | 13% Cr. S.S/CF8/CF8M | A182 F6/F304/F316 |

| S.S 304/304L ASTM A351 GR.CF8/CF3 | A351 Gr. CF8/CF3 | A182 F304/304L |

| S.S 316/316L ASTM A351 GR.CF8M/CF3M | A351 Gr. CF8M/CF3M | A182 F316/316L |

| DUPLEX AND SUPER DUPLEX S.S. ASTM A 995 Gr. 1A, 1B, 1C, 2A, 3A, 4A, 5A, 6A | DUPLEX/SUPER DUPLEX S.S TO SUIT BODY | DUPLEX/SUPER DUPLEX S.S. |

| SUPER ALLOY STEEL- HASTELLOY Gr. B & C | HASTELLOY Gr. B & C | HASTELLOY Gr. B & C |

| INCONEL ASTM B564 UNS N06625 & 600 | UNS N06625 & 600 | UNS N06625 & 600 |

| FORGED ALLOY STEEL- ASTM A182 F11, F22 etc. | A182 F6/F304/316 | A182 F6/F304/316 |

| FORGED DUPLEX & SUPER DUPLEX STAINLESS STEEL ASTM A182 F51, F53, F555 etc. | A182 F51/F53/F55 etc. | A182 F51/F53/F55 etc. |

| FORGED STAINLESS STEEL ASTM A182 F304/304L/ F316/316L | F304/304L/F316/316L | F304/304L/F316/316L |

| DUCTILE IRON/SG IRON/C.I. OF DIFFERENT GRADES | 13%CR.SS/CF8/CF8M | A182 F6/F304/F316 |

Key Features of VALSTEER Dual Disc / Dual Plate Check Valves

- Versatile Installation: Suitable for both horizontal and vertical installations, our dual disc check valves offer flexibility in system design.

- Compact Design: Our valves are designed for space efficiency, requiring less installation space compared to conventional swing check valves.

- Lightweight Construction: Reduces installation and maintenance costs, while enhancing system performance.

- Spring-Loaded Disc: Ensures reliable operation in any mounting position, providing quick response to flow changes.

- Tight Shut Off: Designed for varied fluid types, ensuring reliable protection against backflow in a wide range of applications.

- Minimum Differential Pressure Operation: Operates effectively with minimal differential pressure, enhancing system efficiency.

Why Choose VALSTEER Dual Plate Check Valve?

- Innovative Design: Our valves are crafted with precision, incorporating features that meet the specific challenges of our clients.

- Quality Assurance: With ISO 9001:2015 certification, we guarantee the highest standards of quality across all our products.

- Custom Solutions: We understand that one size does not fit all. That's why we offer valves tailored to your specific operational needs.