VALSTEER Ball Valves : Precision Engineered for Optimal Performance

Phoenix ValSteer is at the forefront of ball valve manufacturing, offering a comprehensive range of solutions designed for high reliability and efficiency across various applications. VALSTEER Ball Valves are meticulously engineered in accordance with the latest international standards, including API 6D and BS 5351, to ensure superior safety, efficiency, and precision.

Our VALSTEER Ball Valve Ranges

Two Piece and Three piece design Ball Valves are regularly manufactured by us. Both these designs are very common in process industries. While two piece design is very safe, three piece design is maintenance friendly as replacement of the body seat is more simple in it.

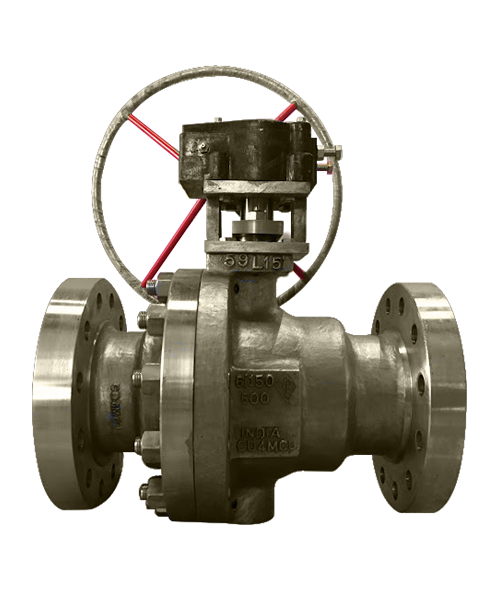

Generally VALSTEER Ball Valves in 150# Valves up to 150 NB, 300# and 600# Valves up to 100 NB and higher pressure ratings like 900# and higher ratings of 50 NB and higher sizes are provided with Trunnion Mounting Balls and Manual Gear operation feature. These features are subject to modification according to customer requirements.

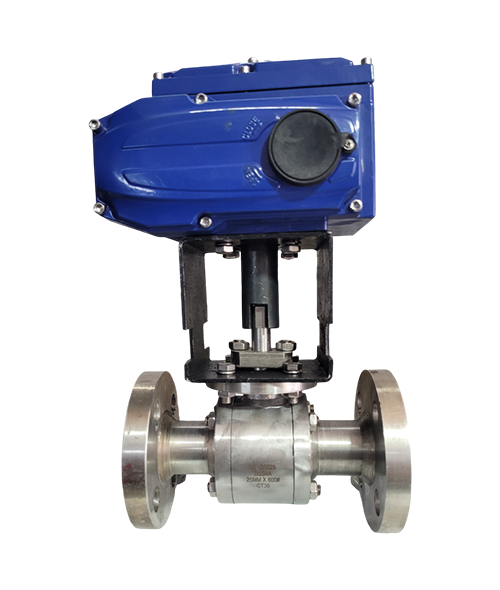

Two - Piece Ball Valve

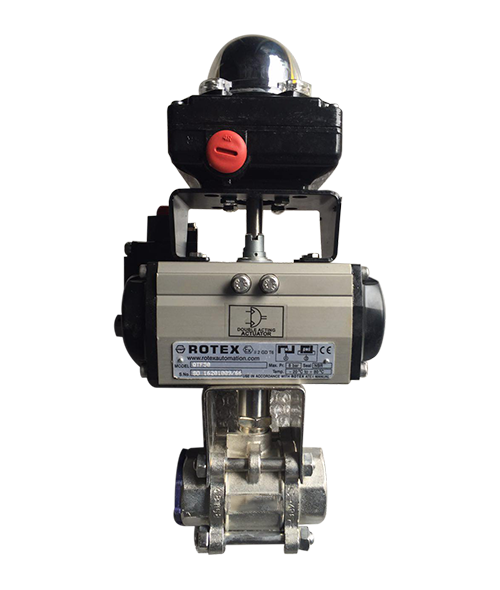

Three - Piece Ball Valve

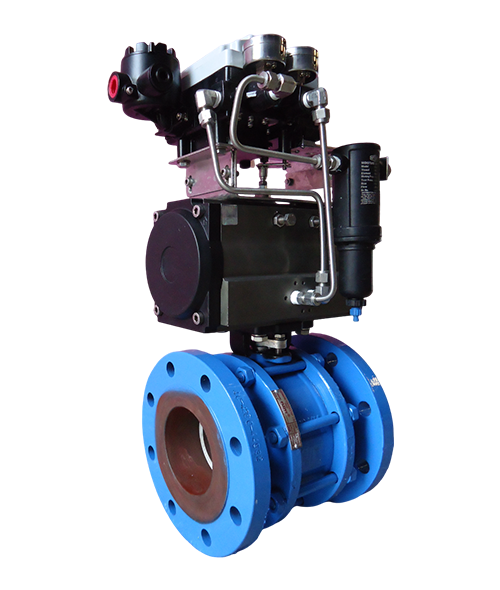

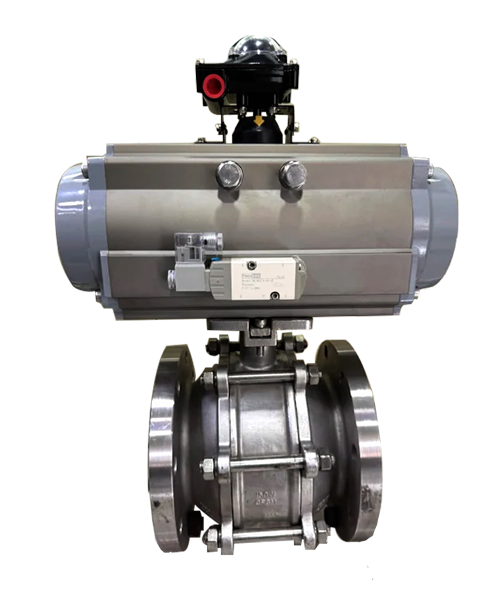

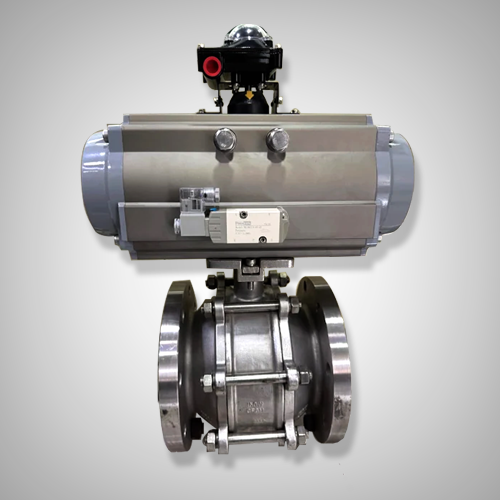

Trunnion - Mounted Ball Valve

Floating Ball Valve

V - Port Ball Valve

Full Bore Ball Valve

Technical Specification

Size

DN50-DN600

Pressure Rating

150#, 300#, 600#, 900#, 1500#

Design Standard

API 6D, BS 5351

MOC

| BODY – BONNET | SEAT/DISC | STEM |

|---|---|---|

| CAST CARBON STEEL ASTM A216 GR.WCB/WCC | 13% Cr. S.S. | A 182 F6 |

| CAST STEEL ASTM A352 GR LCB AND LCC | A351 CF8 | A 182 F304 |

| ALLOY STEEL ASTM A217 GR WC1, WC4, WC5, WC6, WC9, WC11, C5 & C12 | 13% Cr. S.S/CF8/CF8M | A182 F6/F304/F316 |

| S.S 304/304L ASTM A351 GR.CF8/CF3 | A351 Gr. CF8/CF3 | A182 F304/304L |

| S.S 316/316L ASTM A351 GR.CF8M/CF3M | A351 Gr. CF8M/CF3M | A182 F316/316L |

| DUPLEX AND SUPER DUPLEX S.S. ASTM A 995 Gr. 1A, 1B, 1C, 2A, 3A, 4A, 5A, 6A | DUPLEX/SUPER DUPLEX S.S TO SUIT BODY | DUPLEX/SUPER DUPLEX S.S. |

| SUPER ALLOY STEEL- HASTELLOY Gr. B & C | HASTELLOY Gr. B & C | HASTELLOY Gr. B & C |

| INCONEL ASTM B564 UNS N06625 & 600 | UNS N06625 & 600 | UNS N06625 & 600 |

| FORGED ALLOY STEEL- ASTM A182 F11, F22 etc. | A182 F6/F304/316 | A182 F6/F304/316 |

| FORGED DUPLEX & SUPER DUPLEX STAINLESS STEEL ASTM A182 F51, F53, F555 etc. | A182 F51/F53/F55 etc. | A182 F51/F53/F55 etc. |

| FORGED STAINLESS STEEL ASTM A182 F304/304L/ F316/316L | F304/304L/F316/316L | F304/304L/F316/316L |

| DUCTILE IRON/SG IRON/C.I. OF DIFFERENT GRADES | 13%CR.SS/CF8/CF8M | A182 F6/F304/F316 |

Key Features of VALSTEER Ball Valve

- Anti Blowout Stem: Incorporates a specialized stem seal and anti-blowout design, ensuring zero leakage for enhanced operational safety and longevity.

- Mirror Finished Balls: Features precision-polished stainless steel balls for bubble-tight sealing and reduced operating torque, improving durability and performance across the range.

- End Connections: Available in a variety of end connections including Threaded, Socket Weld, Butt Weld, Victaulic, and Flanged (Raised Face and Ring Type Joint), meeting the demands of industries such as Oil & Gas, Petrochemical, Desalination, Water Treatment, Power Generation, Nuclear & Atomic Energy, Chemical Processing, Fertilizers, and Fuel Oil Control.

- Firesafe Design: Ball valves with 300# and higher pressure ratings feature a Fire Safe design with anti-static devices. This is also available on request for lower pressure valves.

- Low Operating Torque: Easy operation with minimal effort, reducing fatigue and improving usability.

Why Choose VALSTEER Ball Valve?

- Innovative Design: VALSTEER valves are engineered for performance, incorporating advanced features to meet the specific needs of our customers.

- Quality Assurance: With ISO 9001:2015 certification, we ensure the highest standards of quality across all our products.

- Custom Solutions: We offer custom-engineered valves to meet unique operational challenges, ensuring optimal performance and reliability.