When you’re dealing with seawater, corrosion is not just a concern — it’s the enemy. Desalination plants run 24/7, pushing high-salinity fluids through filtration and pressure systems that can wear down equipment fast. That’s where Phoenix ValSteer valves come in.

We engineer valves that stand up to brine, scaling, and continuous operation. Whether it’s high-pressure intake, chemical dosing, or backwash lines, we deliver valves that keep desalination systems running smoothly and safely.

The Role of Valves in Desalination Plants

Challenges Faced in Desalination Valve Applications

- Corrosive media with high chloride content

- Scaling from minerals and salts

- Continuous operation with minimal shutdown tolerance

- Compatibility with chemical dosing (chlorine, antiscalants, etc.)

- High-pressure operation in reverse osmosis systems

- Need for tight shut-off and reliable sealing

Where Our Valves Are Used in Desalination Plants

Phoenix ValSteer valves are deployed across all key zones of desalination plants:

- Seawater intake lines : Duplex and super duplex gate valves to resist chloride corrosion

- Pre-treatment and filtration : Knife gate valves to handle sand, silt, and debris

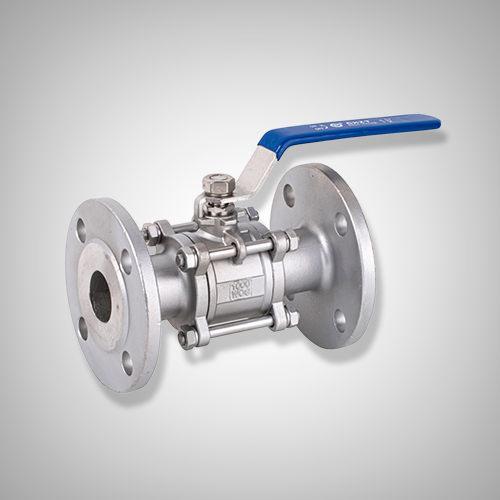

- High-pressure pumps and RO systems : Class 600 globe and ball valves for isolation and throttling

- Chemical dosing lines : SS316 and PTFE-lined valves compatible with corrosive chemicals

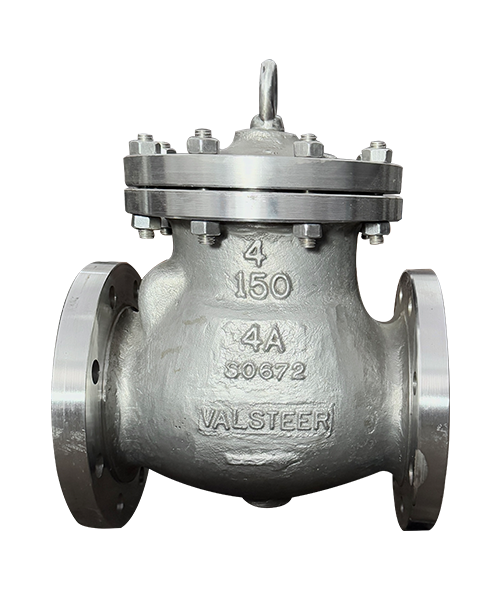

- Backwash and brine reject systems : Swing check valves to manage reverse flow

Recommended Valve Types and Pressure Classes

Valve Type | Pressure Class Range | Common Materials | Typical Application |

Gate Valve | Class 150 to 600 | CF8M, Duplex, Super Duplex | Seawater intake and brine reject lines |

Ball Valve | Class 150 to 600 | CF8M, Super Duplex | High-pressure isolation in RO systems |

Globe Valve | Class 150 to 600 | SS316, CF8M | Throttling in RO and chemical dosing loops |

Check Valve | Class 150 to 600 | Super Duplex, CF8M | Preventing reverse flow in pump discharge and reject streams |

Knife Gate Valve | Class 150 to 300 | SS316, Duplex | Sand and silt handling during filtration |

Material Selection for Desalination Valve Applications

We select materials based on their proven resistance to saltwater, scaling, and chemical attack:

- Super Duplex (UNS S32750, S32760) : Exceptional for chloride resistance and seawater handling

- Duplex Steel (UNS S31803) : High strength and corrosion resistance for general plant use

- Stainless Steel (SS316, CF8M) : Standard for brine and chemical dosing

- PTFE-lined options : For aggressive chemical lines

- All materials are tested for corrosion resistance and available with NACE MR0175 certification if required

Why Choose Phoenix ValSteer for Desalination Valves?

- Built for Salinity : Our valves are designed specifically for seawater and brine service

- Field-Proven in Gulf Projects : Installed in plants across the Middle East

- Zero Compromise on Materials : We only use certified castings with full traceability

- Fast Turnaround for Projects : Responsive support and reliable lead times

- Application Expertise : Recommendations tailored to your P&ID and service media

Ensure Clean Water Flow with Valves That Don’t Fail

Desalination systems demand reliability, corrosion resistance, and performance under pressure. Phoenix ValSteer delivers on all fronts — and we’re ready to support your next project with custom-engineered valve solutions.