In chemical processing plants, everything flows — and every flow matters. From acids and solvents to steam, gas, and slurries, your valves must handle extreme temperatures, corrosive media, and tight shut-off requirements without fail.

At Phoenix ValSteer, we manufacture industrial valves designed specifically for chemical and petrochemical operations. With a wide range of corrosion-resistant materials, pressure classes, and flow control designs, our valves are engineered to protect your process, your equipment, and your uptime.

What the Chemical Industry Needs from Its Valves

Chemical processing involves transforming raw materials into valuable compounds through complex reactions, distillations, and heat or pressure treatment. These processes require valves that can withstand highly corrosive fluids, toxic gases, high temperatures, and aggressive cleaning agents.

A single leak or failure can lead to contamination, costly shutdowns, or serious safety risks. That’s why choosing the right valves — and the right partner — matters.

Common Challenges in Chemical Valve Applications

- Highly corrosive fluids (acids, chlorides, alkalis, solvents)

- Extreme temperature variations in batch and continuous processes

- Vapor and gas handling at high pressures

- Compatibility with steam sterilization and CIP systems

- Media containing solids, slurries, or crystallizing chemicals

- Precise control and zero-leakage isolation in hazardous environments

Where Our Valves Are Used in Chemical Plants

Phoenix ValSteer valves are used in a wide range of applications across the chemical and petrochemical sectors:

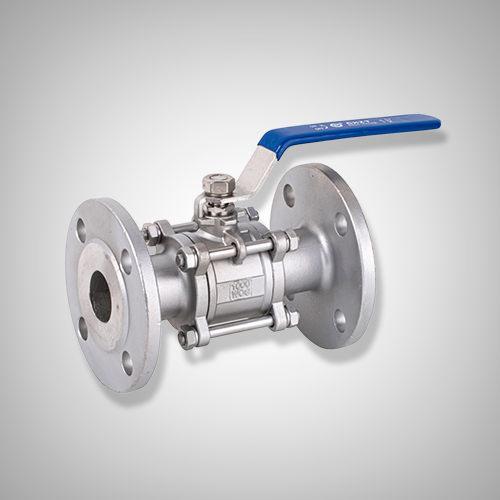

- Acid lines and chemical reactors: Globe valves and ball valves in PTFE-lined or alloy materials

- Distillation and recovery columns : Gate valves and globe valves in SS316 and CF8M

- Solvent and gas lines : High-pressure ball valves with fire-safe design

- Effluent and waste handling : Knife gate valves for slurry, sludge, and neutralization systems

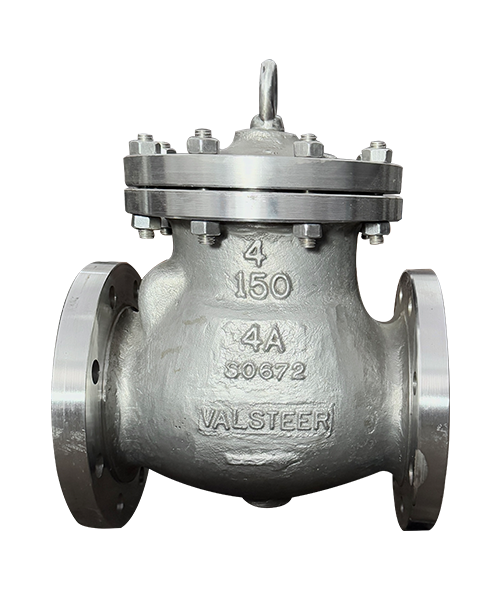

- Tank farms and transfer lines : Swing check valves to prevent backflow during loading/unloading

Recommended Valve Types and Pressure Classes

| Valve Type | Pressure Class Range | Common Materials | Typical Application |

| Ball Valve | Class 150 to 1500 | CF8M, SS316, PTFE-lined, Alloy 20 | Acid and solvent transfer lines |

| Globe Valve | Class 150 to 600 | CF8, SS316, Hastelloy | Flow control in reactors and heating loops |

| Gate Valve | Class 150 to 600 | WCB, CF8M, Duplex | Isolation in utility and feed systems |

| Check Valve | Class 150 to 600 | CF8M, SS316, Super Duplex | Backflow prevention in loading bays and fluid circulation |

| Knife Gate Valve | Class 150 to 300 | SS316, Duplex | Slurry and chemical waste discharge |

Material Selection for Chemical Applications

- CF8M / SS316 : Standard for acids, alkalis, and high-purity fluids

- PTFE / FEP / PFA linings : For highly corrosive chemicals and aggressive cleaning agents

- Duplex / Super Duplex : For mixed chemical and brine services

- Alloy 20 and Hastelloy C : Excellent resistance to sulfuric acid and oxidizing media

- All valves are available with full MTCs and can meet NACE, API, and PED standards

Why Choose Phoenix ValSteer for Chemical Plant Valves?

- Media-Matched Expertise : We recommend the right valve material for your specific fluid, not just a generic spec

- Full Range of Lined and Metal Valves : PTFE-lined ball and plug valves available on request

- Leak-Proof Performance : Zero leakage standards for critical chemical lines

- Traceable Quality : Every valve tested, certified, and documented

- Custom Builds : Special trims, face-to-face dimensions, and actuation options available

Control the Flow. Contain the Risk.

Chemical plants can’t afford leaks, downtime, or subpar materials. Phoenix ValSteer delivers valves that perform under pressure, resist the most corrosive media, and help your process stay safe, efficient, and compliant.