In pharmaceutical manufacturing, consistency isn’t optional — it’s critical. Whether you’re handling purified water, CIP fluids, clean steam, or corrosive chemicals, your valves must offer uncompromising cleanliness, leak-tight sealing, and material integrity.

At Phoenix ValSteer, we provide high-performance valves built to meet the stringent standards of pharmaceutical production. From API manufacturing to biotech and formulation units, our valves help ensure safe, sterile, and reliable process flow.

What the Pharmaceutical Industry Demands from Valves

Pharmaceutical production involves highly sensitive, tightly regulated processes where contamination, pressure loss, or valve failure can compromise entire batches. Valves must be cleanable, corrosion-resistant, and compatible with aggressive chemicals and sterilization systems.

Our valve range supports the core principles of pharmaceutical plant design — hygiene, safety, and process efficiency.

Common Challenges in Pharmaceutical Valve Applications

- Maintaining sterility in product-contact valves

- Resistance to aggressive acids and solvents

- Reliable sealing in high-purity water and clean steam systems

- Compatibility with CIP (Clean-in-Place) and SIP (Steam-in-Place) protocols

- Compliance with FDA, USP Class VI, and ASME BPE standards

- Avoiding contamination and ensuring full drainability

Where Our Valves Are Used in Pharmaceutical Plants

Phoenix ValSteer supplies valves across key pharmaceutical process areas:

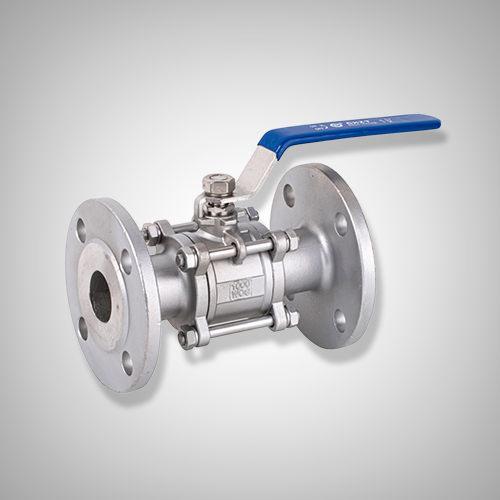

- Purified water and WFI lines – Stainless steel globe and ball valves for clean isolation

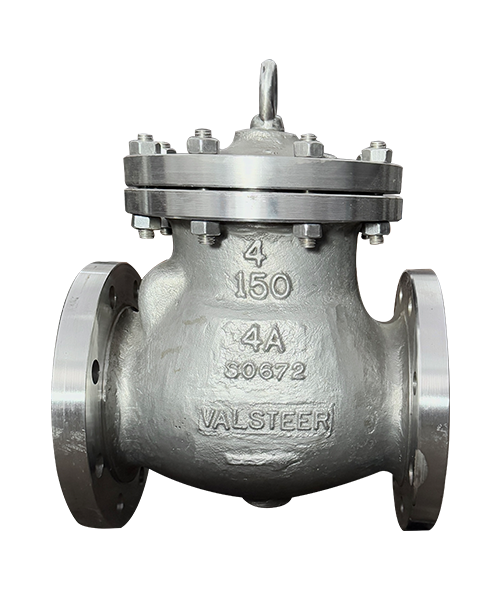

- Clean steam systems – Class 150 globe valves in CF8M for sterile flow control

- Acid and solvent dosing – PTFE-lined valves for corrosion resistance

- Utility and CIP lines – Ball and check valves for safe, reliable flow

- Effluent treatment – Knife gate and check valves for neutralization and discharge systems

Recommended Valve Types and Pressure Classes

Valve Type | Pressure Class Range | Common Materials | Typical Applications |

Globe Valve | Class 150 to 600 | SS316, CF8M | Flow control in clean steam and purified water lines |

Ball Valve | Class 150 to 600 | SS316, CF8M, PTFE-lined | Isolation in solvent, buffer, and acid systems |

Check Valve | Class 150 to 300 | SS316, CF8M | Preventing backflow in purified media and utility services |

Knife Gate Valve | Class 150 to 300 | SS316 | Handling effluent, sludge, or semi-solid discharge from batch plants |

Gate Valve | Class 150 to 600 | WCB, SS316 | Utility and general service pipelines |

Materials We Offer for Pharmaceutical Service

All materials are selected to meet hygienic, corrosion-resistant, and regulatory standards:

- SS316 / CF8M : For high-purity media, clean steam, and buffer solutions

- PTFE / PFA / FEP Linings : For strong acid, base, and solvent resistance

- WCB / CS : For non-contact utility and effluent systems

- Valves can be offered with electropolished or hygienic internal finishes on request

All materials are traceable and supported with test certificates, FDA or USP Class VI compliant elastomers, and third-party inspection where required.

Why Phoenix ValSteer for Pharmaceutical Valves?

- Clean by Design : Crevice-free, drainable valves for hygienic installations

- Material Integrity : All wetted parts meet ASTM, FDA, and international standards

- Process Safety : Fire-safe and blowout-proof stem designs available

- Custom-Built for Projects : Support for plant expansions, cleanroom piping, and pilot projects

- Responsive Engineering Support : Fast quotation, technical drawings, and delivery

Control Flow. Preserve Purity. Trust Phoenix ValSteer.

From formulation to final fill, your process depends on valves that meet the highest standards. Phoenix ValSteer is your partner for high-integrity valve solutions that support clean, compliant, and efficient pharmaceutical manufacturing.