Water is life — but only when it flows clean and controlled. Whether you’re treating surface water, distributing drinking water, or managing industrial and municipal wastewater, your valves need to handle varying pressures, flow rates, solid content, and corrosive chemicals with zero compromise.

At Phoenix ValSteer, we design valves specifically for the demands of water and wastewater treatment plants. From raw water intake to final discharge, our products ensure reliable, maintenance-friendly operation across every stage of treatment.

Why Valves Matter in Water and Wastewater Facilities

Water and wastewater treatment plants rely on mechanical and chemical processes to clean, disinfect, and safely release or reuse water. Valves play a crucial role in managing flow, isolating lines for maintenance, handling backpressure, and dosing chemicals.

System uptime and regulatory compliance depend on valves that operate reliably through sediment, sludge, chlorination, and fluctuating flow conditions.

Key Challenges in Water & Wastewater Valve Applications

- Handling fluids with suspended solids, grit, and sludge

- Resistance to chlorinated and chemical-laden water

- Managing flow during fluctuating demand and surge pressure

- Corrosion resistance in underground or outdoor installations

- Long service life with minimal maintenance in remote locations

- Compliance with water safety and discharge regulations

Where Our Valves Are Used in Water Treatment Systems

Phoenix ValSteer valves are installed across the full cycle of water and wastewater infrastructure:

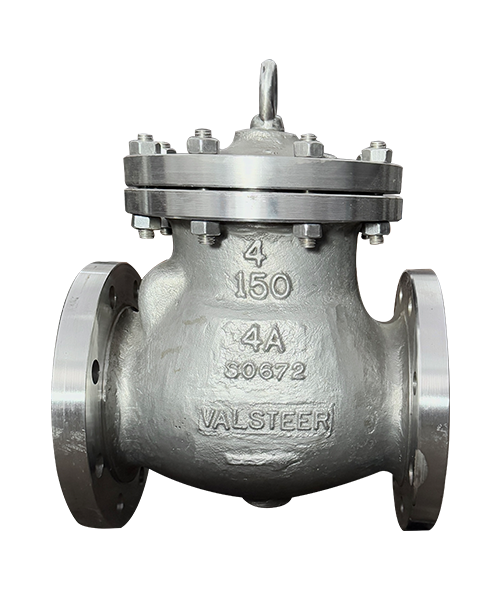

- Raw water intake – Gate valves and check valves with corrosion-resistant trims

- Sand and media filters – Knife gate valves for backwash and solid removal

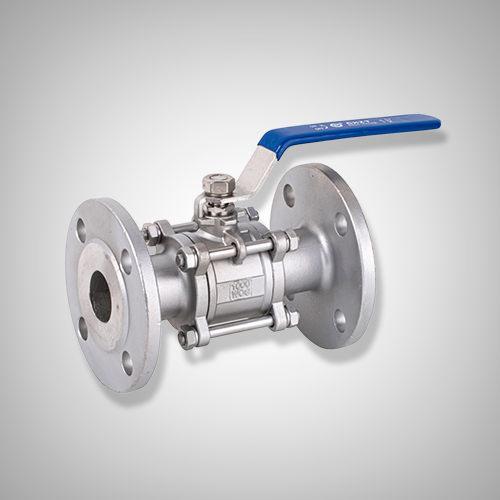

- Chemical dosing stations – SS316 and PTFE-lined valves for chlorination and pH control

- Settling tanks and clarifiers – Sludge-handling knife gate valves

- Pump stations and discharge lines – Swing check valves and butterfly valves for flow protection

Recommended Valve Types and Pressure Classes

Valve Type | Pressure Class Range | Common Materials | Typical Application |

Gate Valve | Class 125 to 300 | CI, DI, CF8, SS316 | Isolation in intake and distribution pipelines |

Knife Gate Valve | Class 150 to 300 | SS304, SS316, Duplex | Sludge handling, grit removal, and sediment lines |

Ball Valve | Class 150 to 600 | CF8M, SS316, PTFE-lined | Isolation and shut-off in chemical and control loops |

Check Valve | Class 150 to 300 | CF8M, CI, DI, Super Duplex | Preventing backflow in treated and discharge water systems |

Butterfly Valve | Class 150 to 300 | CI, DI, Epoxy-Coated, SS316 | General flow control in large-diameter lines |

Material Options for Water and Wastewate Applications

Different stages of treatment call for different materials. Phoenix ValSteer offers:

- Cast Iron / Ductile Iron (CI/DI) : Economical choice for general water lines

- SS304 / SS316 / CF8M : Excellent corrosion resistance in chemical and treated water

- PTFE-lined valves : For aggressive chemical dosing and pH control

- Duplex Stainless Steel : Ideal for high-chloride, brackish, or industrial effluent

- Epoxy Coated Bodies : Extra protection for buried or submerged service

All valves are available with rubber-seated or metal-seated options, depending on flow media and operating conditions.

Why Choose Phoenix ValSteer for Water Sector Valves?

- Sludge? No problem. We build knife gate valves that handle thick slurry and grit without clogging

- Built for corrosion zones. From buried service to chemical exposure, our material selection ensures long life

- Low Maintenance, High Uptime. Designed for treatment plants that run around the clock

- Fast Project Support. We support contractors and EPCs with responsive lead times and documentation

- Certifications and Compliance. API, ISO, and optional potable water certifications

Ready to Equip Your Plant with Trusted Valve Solutions?

Whether you’re building a new STP or upgrading a 20-year-old WTP, Phoenix ValSteer can support your project with durable, efficient valves tailored for your application.